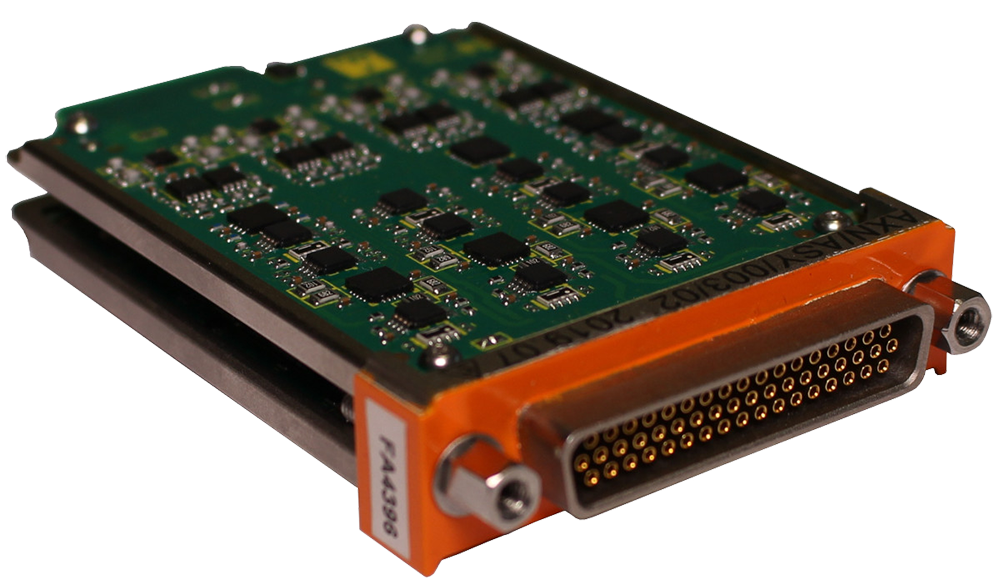

New Axon AXN/ADC/406 and ADAU ARTD-416A-1 modules support 16 RTD channels in a single slot with extremely high accuracy

ASHBURN, Va. – May 11, 2020 – Curtiss-Wright’s Defense Solutions division today announced that it's Aerospace Instrumentation (AI) group, a trusted leading supplier of flight test instrumentation (FTI) system solutions, has introduced two analog-to-digital-conversion (ADC) module variants for use with Resistance Temperature Detector (RTD) sensors used in flight test and monitoring programs to accurately measure the temperature of engines and other critical components. The ability to connect to multiple RTDs from a single highly accurate ADC module enables FTI engineers to save valuable weight, slot count, and cost when configuring their FTI data acquisition unit (DAU).

The new AXN/ADC/406 modules are designed for use with Curtiss-Wright’s AXN family of DAUs, while the ARTD-416A-1 is optimized for use with Curtiss-Wright’s TTC family of ADAUs. Both variants can acquire sensor data from up to 16 RTD channels on a single module. Unlike legacy products that restrict all channels on similar cards to the same RTD type, the AXN/ADC/406 and ARTD-416A-1 enable different RTD types to be supported on each channel. These ADCs can be configured as either 2-wire or 3-wire and provide maximum sampling rates of 6.25 ksps per channel with a measurement bandwidth of 1.5625 kHz. With a temperature input range of -200°C to 850°C, these two compact modules deliver extremely high accuracies:

- Typical 0.25°C between -50°C and +250°C for PT-100 with 2.5mA excitation

- Typical 0.4°C between -200°C and +660°C for PT-100 with 1.5mA excitation

- Typical 0.25°C between -50°C and +250°C for PT-1000 with 2.5mA excitation

- Typical 0.4°C between -200°C and +660°C for PT-1000 with 1.5mA excitation

“We are excited to continue to add industry-leading functionality to our range of fully integrated data acquisition systems for flight text programs,” said Lynn Bamford, President, Defense, and Power. “With the introduction of these new ADC modules for RTC temperature sensors, we further enhance the capabilities of our Axon and TTC DAU solutions, with support for a huge number of channels on a single module and industry-leading signal accuracies. Even better, they add flexible RTD support, error correction, and advanced filter settings to deliver unmatched capability.”

Axon AXN/ADC/406 and ADAU ARTD-416A-1 Performance Features

- 16 × 2-wire or 3-wire input channels.

- All RTD types

- Different RTD Types per channel

- Input range -200°C to 850°C

- High accuracy:

- 0.25°C (Typical) between -50°C and 250°C

- 0.6°C (Typical) between -200°C and 660°C

- Programmable dual range, constant current excitation per channel

- Short on any channel does not affect others

- 16-bit simultaneous sampling on each channel

- 3 filter tap points per channel, each with configurable filtering type and filter cutoff settings

- User-defined linearization and error compensation across the entire measurement chain

- Software Support:

- The user interface for setup and management of data acquisition, network switches, recorders, and ground stations in an integrated environment

- AXN/ADC/406: DAS Studio 3

- ARTD-416A-1: TTCWare

- The user interface for setup and management of data acquisition, network switches, recorders, and ground stations in an integrated environment

The Benefits of Complete DAU System Solutions

Curtiss-Wright’s Axon chassis, Axon user modules, and Axonite remote housing are designed to work with Curtiss-Wright’s aerospace instrumentation products including TTC DAU, TTC MnACQ, TTC MnHSD, and KAM-500 DAU family of data acquisition systems, high-speed cameras, data recorders, switches, and IADS display and analysis software. Axon DAUs provide the most powerful and modern solution on the market by combining unprecedented flexibility with outstanding reliability for demanding applications. Axon modules and chassis, now available in 6, 9, and 16-slot configurations, enable FTI engineers to quickly configure and deploy the vast amounts of data acquisition required to support demanding flight tests, missile tests, and space developmental/operation flight instrumentation programs. These systems are ideal for use in flight tests, system monitoring, power system upgrades, or life extension programs.

About Curtiss-Wright Corporation

Curtiss-Wright Corporation is a global innovative company that delivers highly engineered, critical function products and services to the commercial, industrial, defense and energy markets. Building on the heritage of Glenn Curtiss and the Wright brothers, Curtiss-Wright has a long tradition of providing reliable solutions through trusted customer relationships. The company is headquartered in Davidson, N.C., and employs approximately 9,100 people worldwide. For more information, visit www.curtisswright.com.

###

Note: All trademarks are property of their respective owners.